All Metal Roofing’s polycarbonate and fibreglass roofing supplies are manufactured by Ampelite, Australia’s largest and most experienced manufacturer of polycarbonate and fibreglass roof sheeting. Ampelite has been manufacturing polycarbonate and fibreglass roof sheet since 1969 and was awarded with ISO90001: 2015 SAI Quality Endorsed Company.

Ampelite’s Translucent and Polycarbonate sheets that we offer include Solasafe Polycarbonate, Lexan Thermoclear (Twinwall and Multiwall Polycarbonate), and Fibreglasses (Permaglas and Wonderglas GC), with the supporting accessories and fittings to complete your translucent roofing needs.

‘Solasafe’ Polycarbonate sheeting provides 99% protection from harmful UV rays that cause sunburn and skin damage. Outdoor family and children’s play areas are part of the Australian lifestyle, and selecting the best roofing solution is the first step to ensure you get the maximum benefit from your investment. Polycarbonate is an advanced polymer with optical and physical properties that can’t be matched by other materials. Adding an outdoor room to your home can enhance your family life and add value to your property. Solasafe has three levels of polycarbonate sheeting to choose from. A level to suit your needs and climate. A colour to suit your home and surroundings.

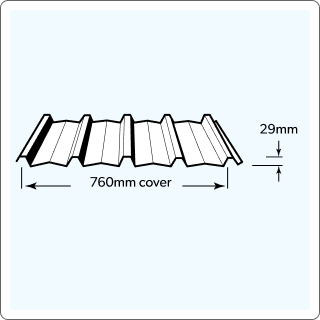

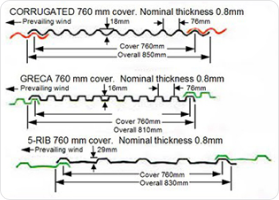

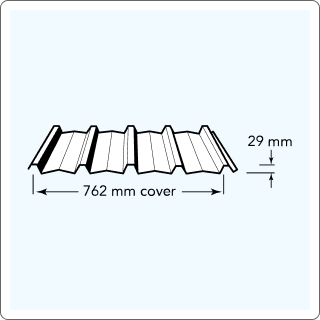

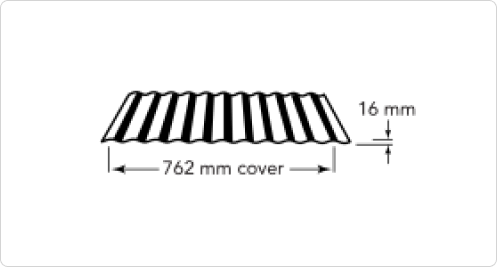

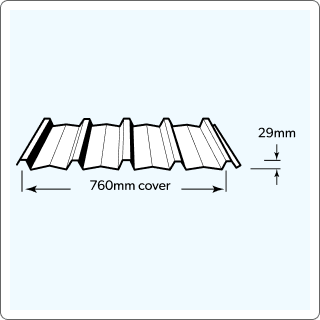

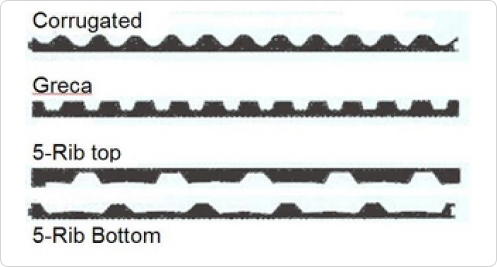

The most widely used Solasafe Polycarbonate sheet. Available in Corrugated, Greca and 5 – Rib profiles. Seven colours with varying light and heat transmission ratings.

In designer colours that transmit less heat but allow plenty of soft light to pass through. More comfort! Corrugated and Greca profiles. Two colours according to the profile selected.

Metallic particles reflect heat but allow soft diffused light to transmit. Especially suitable for use in hot climates. Corrugated and Greca profiles in Pearl Ice and Silvermist colours.

Available Domestic Profiles

Ampelite Domestic Fibreglass sheeting is available in the following profiles:

Colours available / Light and Heat transmission:

| Colours available | Light% | Heat% |

|---|---|---|

| Clear | 91 | 85.2 |

| Opal | 55 | 40.2 |

| Grey | 26 | 50 |

| Light Bronze | 36 | 60.6 |

| Dark Tint | 17 | 38.9 |

| Wheat | 30 | 38.1 |

| Green | 48 | 65 |

| Smooth Cream | 44 | 35.2 |

| Mist Green | 40 | 37.3 |

| Pearl Ice | 48 | 32.5 |

| Silver Mist | 17 | 22 |

Sheet Lengths:

| Colours | Lengths | Profiles |

|---|---|---|

| Clear | 1.8 – 8.1m | All profiles |

| Opal, Lt. Bronze, Grey | 1.8 – 8.1m | Crega, Corrugated |

| Opal, Lt. Bronze, Grey | 1.8 – 6.0m | 5-Rib |

| Dark tint, Wheat, Green | 1.8 – 6.0m | Corrugated only |

Lengths available for domestic use: 1.8m, 2.1m, 2.4m, 2.7m, 3.0m, 3.6m, 4.2m, 4.8m, 5.4m, 6.0m, 8.1m

Domestic Spanning Capacity:

| Profile | 1 sheet | 2 sheets | 3 sheets | 4 sheets | 5 sheets |

|---|---|---|---|---|---|

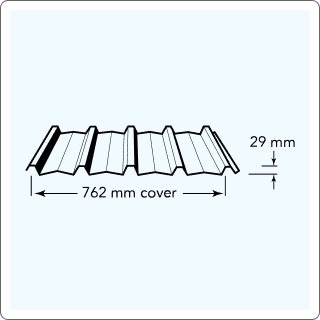

| Corrugated | 760mm | 1620mm | 2380mm | 3140mm | 3900mm |

| 5-Rib | 760mm | 1570mm | 2330mm | 3090mm | 3850mm |

| Greca | 760mm | 1570mm | 2330mm | 3090mm | 3850mm |

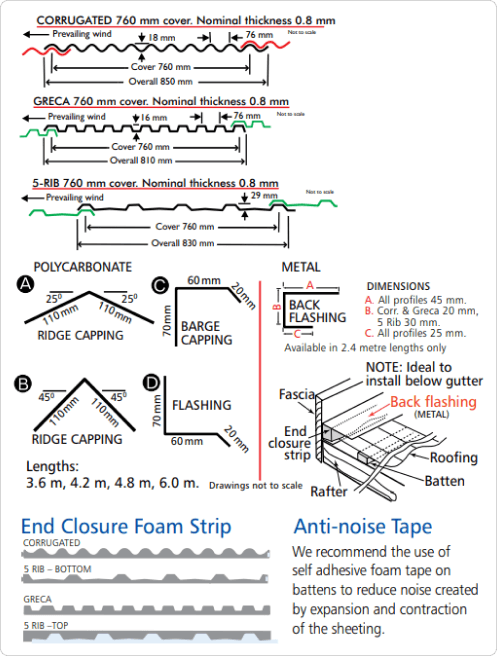

Corrugated sheets should have 1.5 overlaps, 1 rib only on 5-Rib sheets and Greca. Overlaps should face away from the prevailing wind.

Light transmission in accordance with AS/NZS 4257.4

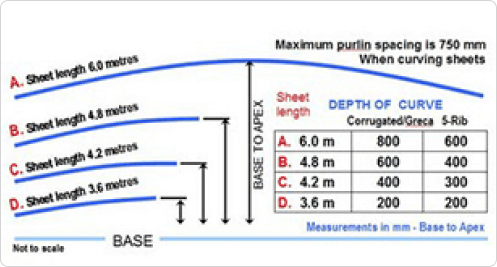

Maximum Recommended Curves:

Cuts 99% of harmful UV Rays

You can enjoy the outdoors feeling yet be protected from the sun, because Ampelite glass reinforced polyester sheeting has inbuilt protection against the transmission of harmful ultra violet rays. Sun without sunburn.

Australian Made

Ampelite sheeting is made to stand up to tough Australian conditions from Cairns to Cradle Mountain. When you choose Ampelite glass reinforced sheeting you can be sure that it has been made from the highest quality materials available using the world’s latest resin technology. Ampelite’s manufacturing process ensures that each phase of production is absolutely consistent from batch to batch.

Polyester film surface protection

This tough film forms an integral part of the sheet and increases its life as it prevents reinforcing fibres becoming exposed on the surface of the sheet.

Corrugated

Traditional, corrugated roofing & walling

Planning

There are so many ways to use Ampelite ‘Corri-glas’ and ‘Trim-glas. And, the cost is moderate, so it’s good value too. If you want plenty of light, lasting protection from the sun, and a great home feature, start by drawing up a simple plan.

Ampelite sheeting is lightweight and easy to handle and install. Even projects such as an outdoor living area or carport can be a satisfying Do-It-Yourself job.

Before you order materials or commence to build you should check that your proposed work complies with local council by-laws. Minimum recommended roof pitch is 5º.

The tables below give you the maximum span between battens or purlins for the 1200 and 1800 series sheeting. Sheet lengths available are also shown, and the ‘Sheet coverage table’ helps you calculate how many sheets to buy.

Spanning Capacity – Domestic and Heavy Duty Grades

| Profile | Series | Max.Span |

|---|---|---|

| Corri-glas’ (Corrugated) | 1200 | 750mm |

| 1800 | 1000mm | |

| Trim-glas’ (5 Rib) | 1200 | 900mm |

| 1800 | 120mm |

The span between battens or supports should not exceed the above measurements

Sheet Coverage Table

| Profile | 1 sheet | 2 sheets | 3 sheets | 4 sheets | 5 sheets |

|---|---|---|---|---|---|

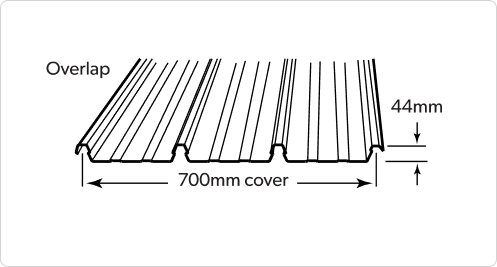

| Corri-glas | 760mm | 1620mm | 2380mm | 3140mm | 3900mm |

| Trim-glas | 760mm | 1580mm | 2340mm | 3100mm | 3860mm |

Corrugated sheets should have 1.5 overlaps, 1 rib only on 5 Rib sheets. Overlaps should face away from prevailing wind

Light and Heat Transmission

| Grade | 1200kg | 1800kg | ||

|---|---|---|---|---|

| Light % | Heat % | Light % | Heat % | |

| Ice Clear | 84 | 82 | 76 | 74 |

| Opal (white) | 84 | 62 | 69 | 62 |

| Emerald Green | 84 | 62 | NA | NA |

| Brown | 84 | 62 | NA | NA |

| Slate Grey | 84 | 60 | 42 | 52 |

| Haze Green (in 1800g only) | NA | NA | 62 | 72 |

The above tests were conducted by a NATA approved research laboratory and are available on request.

Sheet Lengths:

| Profiles: Corrugated and 5 Rib | ||||||

|---|---|---|---|---|---|---|

| 1.800m | 2.100m | 2.400m | 2.700m | 3.000m | 3.000m | 3.600m |

| 3.900m | 4.200m | 4.500m | 4.800m | 5.100m | 5.700m | 6.000m |

In addition to these stock lengths a cut to size service is available through most outlets.

Ampelite Product Grades

| Type | Grade | Weight |

|---|---|---|

| Domestic | Series 1200 | 1.2kg per m2 (4oz) |

| Heavy Duty | Series 1800 | 1.8kg per m2 (6oz) |

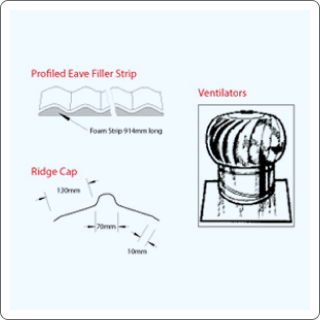

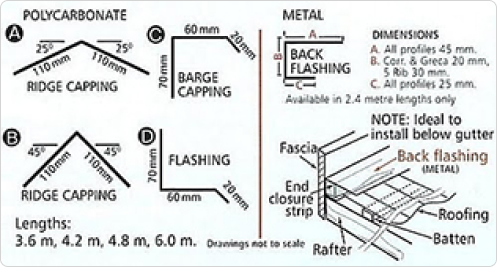

Translucent Ridge Capping can be supplied in both grades

All Metal offer a wide range of Ampelite domestic accessories available onsite at our branches for your convenience.

Good ventilation helps prevent heat build-up and assist in air circulation. If heat can be trapped inside the covered area, it is a good policy to provide ventilation outlets, or use a specially designed ventilator.

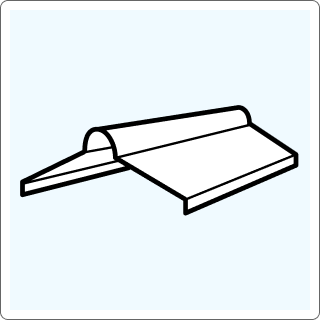

Available in Clear and Opal in lengths up to six metres. Clear suits all colours as it does not increase the density of colour when applied over the roofing.

These foam strips are used at the ends of sheets to prevent the entry of birds, leaves, as well as wind driven rain. Strips available to suit ‘Corri-glas’ and ‘Trim-glas’.

Screws for fixing ‘Corri-glas’ sheets

10g x 50mm self-drilling Multi-drive (Hex/Phillips/Slotted) screws. Packs of 50 with 17mm weatherproof seals.

Screws for fixing “Trim-glas” sheets

The entry of birds, leaves, as well as wind driven rain. Strips available to suit ‘Corri-glas’ and ‘Trim-glas’.

Type 17 screws (hexagon head self-drilling for timber) 12g x 65mm, packed in 25’s with 19mm ‘Duranol’ weatherproof seals.

Permaglas Industrial Fibreglass Sheeting has set the standard for Industrial skylights in Australia for many years. It provides cost effective high levels of light transmission, excellent spanning, and low thermal expansion. The highest quality materials available and the very latest resin technology are used in the manufacturing process making it a durable, cost effective alternative which filters out 99% of harmful UV rays, giving excellent protection from the elements while still letting the sunlight trough. More recently, Ampelite have developed Wonderglas GC, which provides all of the physical properties of standard Industrial Fibreglass, with ultimate durability through Ampelite’s unique Gel Coat Technology.

Available Industrial Profiles and lengths:

Profiles available in Polycarbonate sheeting are limited to Corrugated and Trapezoidal pan (5-Rib). There are no decking profiles.

| Profile | Available length |

|---|---|

| Corrugated | up to 8.1 meters |

| Trimdek (5-Rib) | 6 meters |

The 6 meter maximum length is well justified. Polycarbonate has a thermal co-efficient of 6.75 x 10-5 cm/cm °C, which equates to a linear expansion of up to 16.2mm over a 6 metre run

Industrial spanning capacity:

Maximum allowable spans, wind pressure up

to 1kPa are as follows:

| Profile | Nominal thickness | Maximum Span |

|---|---|---|

| Corrugated | 0.8mm | 0.9 meter |

| Trimdek (5-Rib) | 0.8mm | 1.0 meter |

Polycarbonate is essentially a by-product of the petro-chemical industry. In turn, Polycarbonate is therefore susceptible to chemical reaction, especially to petro-chemical based products.

It is important to note, that even neutral cure silicone should not be applied to Polycarbonate, as it weakens the sheet causing it to rip or fracture, sometimes within weeks of application. If sealant is necessary, use only Seal-Once a special silicone containing polycarbonate. Using incorrect sealant voids the warranty.

While Polycarbonate has a very high impact strength when new, UV degradation substantially lowers this strength. Caution is always required to ensure that the UV protective coating is facing the sun in accordance with the product label or marking.

Safety mesh is always required with Polycarbonate roofing. Polycarbonate is non-trafficable and does not meet the requirements of AS/NZS 1562-3 1996: Resistance to impact (sandbag) for roofing sheet materials.

Alternative Ampelite Industrial sheeting

It is Ampelite’s experience that Polycarbonate has a number of limitations when used in Industrial/Commercial installations. The thermal co-efficient being a significant factor, also the relatively small spanning capacity, limited choice of profiles and general UV degradation. Clear Polycarbonate has unmatched light transmission properties, but this also means very high heat transmission which in many applications is unacceptable.

We have found that when Polycarbonate sheeting is specified, it is usually because the specifier is seeking to select a product, which hopefully, will outperform the industrial grades of fibreglass roofing generally available.

However, Ampelite have made a significant advance with the introduction of ‘Wonderglas GC’ gel coated premium grade industrial sheeting that has a 25 year warranty. The gel coating and base sheet are at the cutting edge of resin technology. UV resistance is so high, that loss of light transmission after 10 years is just 10%, with only minimal change in later years.

‘Wonderglas GC’ outperforms and outlasts other plastic roofing materials and is compatible in all respects to metal roofing. Another option if you did require Polycarbonate would be to use Twinwall, which has many advantages over standard Polycarbonate.

It is important to note, that even neutral cure silicone should not be applied to Polycarbonate, as it weakens the sheet causing it to rip or fracture, sometimes within weeks of application. If sealant is necessary, use only Seal-Once a special silicone containing polycarbonate. Using incorrect sealant voids the warranty.

Ampelite’s Industrial Fibreglass has set the standard for Industrial skylights in Australia for many years. It provides cost effective lighting through excellent spanning, light transmission and low thermal expansion.

More recently, Ampelite have developed Wonderglas GC, which provides all of the physical properties of standard Industrial Fibreglass, with ultimate durability through Ampelite’s unique Gel Coat Technology. For more information on Wonderglas GC and Ampelite’s Gel Coat Technology.

All current profiles (see link below) such as Corrugated, Trapezoidal pan (5-Rib), Speed-dek, etc. plus most superseded profiles are available. Click here to view profiles.

Ampelite industrial & premium grade industrial fibreglass is manufactured to AS/NZS 4256.3: 1994, Licence No.986. Ampelite are an AS/NZS ISO 9001 QEC. N.B. Standard grade is surface protected with Melinex polyester film.

Ampelite warrant series 2400 (and upwards) standard grade industrial fibreglass sheeting against damage from hail up to 20mm in diameter accompanied by winds up to 100 km/hr for 5 years. Premium grade gel coated sheeting is covered for 10 years.

Spanning Capacity

| Industrial Standard and Premium Grades | |||||

|---|---|---|---|---|---|

| Series | 2400 | 3050 | 3660 | 4270 | 4880 |

| Nominal Thickness | 1.4mm | 1.7mm | 2.1mm | 2.45mm | 2.8mm |

| Corrugated | 1200mm | 1500mm | 1700mm | ||

| 5 Rib | 1500mm | 1700mm | 2000mm | 2300mm | |

| Trapezoidal corrugated | 1600mm | 2000mm | 2300mm | 2600mm | 2800mm |

| Standing seam 406 | 1400mm | 1700mm | 2000mm | 2300mm | 2600mm |

| Standing seam 700 | 1400mm | 1700mm | 2000mm | 2300mm | 2600mm |

| Speed-dek | 1400mm | 1700mm | 2000mm | 2300mm | 2600mm |

| LT7 | 1700mm | 2100mm | 2400mm | 2600mm | 2800mm |

The above spans are recommended for wind loads up to 1.0 kPa.

For information regarding recommended spans in high wind and cyclonic regions please contact your local Ampelite office.

Sheeting Grades

| Series | Weight (Kg/m2) |

|---|---|

| 2400 | 2.4 |

| 3050 | 3.05 |

| 3660 | 3.66 |

| 4270 | 4.27 |

| 4880 | 4.8 |

Important: Heavier grades give the specifier the option to use Ampelite sheeting in cyclonic zones, or match the span of the nominated steel roofing material (see ‘Spanning Capacity’).

Light and Heat Transmission

| Series | 2400 | |

|---|---|---|

| Light % | Heat % | |

| Ice Clear | 70 | 68 |

| Opal (white) | 68 | 64 |

For Light and Heat transmission of other series (grades), please contact your local Ampelite office. Other colours can be produced to order for viable quantities.

Expansion Data

| Materials Expansion Comparison. 0° to 40° Temperature Variation. Sheet Length 6 metres | ||||

| Fibreglass | Polycarbonate | Steel | Aluminium | |

| Thermal Expansion | 1.4mm | 16.2mm | 2.9mm | 2.8mm |

| Thermal Co-efficient | 3.0 x 10-5 cm/cm°C | 6.75 x 10-5 cm/cm°C | 1.2 x 10-5 cm/cm°C | 2.4 x 10-5 cm/cm°C |

Physical Properties

| Tensile Strength | 80 MPa |

| Impact Strength | 8 Joules |

| Shear Strength | 90 MPa |

| Modulus of Elasticity | 5500 MPa |

| Compressive Strength | 135 MPa |

| Flexural Strength | 150 MPa |

| Specific Gravity | 1.45 |

| Thermal Expansion | 3.0 x 10-5 cm/°C |

| Thermal Conductivity | 0.158 watt/m°C |

| Water Absorption | .2% in 24hrs./26°C |

| Curved Roof Radius | 2400g/m2 “Corrugated” and “5-Rib” |

| Minimum Radius | 4.0 Metres |

| Recommended Service Temperature Range | -20° to +96°C |

Maximum Recommended Curves:

All Metal offer a wide range of Ampelite polycarbonate accessories available onsite at our branches for your convenience.

End Closures

Ampelite recommend the use of self adhesive tape on battens to reduce noise created by expansion and contraction of the sheeting.

Profiled polycarbonate with the look of glass

Transform your outdoor area into a stunning, light-filled space with Ampelite PolyGlaze®—the ultimate roofing solution for DIY patios, pergolas, walkways, and more.

Designed for easy installation and long-lasting performance, PolyGlaze® brings together the style of glass with the practicality of advanced polycarbonate.

PolyGlaze® delivers the timeless elegance of glass with the lightweight performance and durability of advanced polycarbonate.

Whether you’re building a pergola, veranda, carport, or outdoor walkway, PolyGlaze® offers a sleek, high-end look while protecting your space from the elements.

With a choice of clear or grey tint, PolyGlaze® panels are designed to maximise natural light or provide shade where needed.

Engineered to be tough against hail and wind, UV-resistant, and easy to install, PolyGlaze® is the smart, modern solution for homeowners seeking style, performance, and simplicity—all in one.

Why PolyGlaze® is the Smart DIY Patio Solution

Glass-Look Elegance Without the Cost

Enjoy the sleek, modern appearance of glass with the added safety and affordability of high-performance polycarbonate.

Simple, Stress-Free Installation

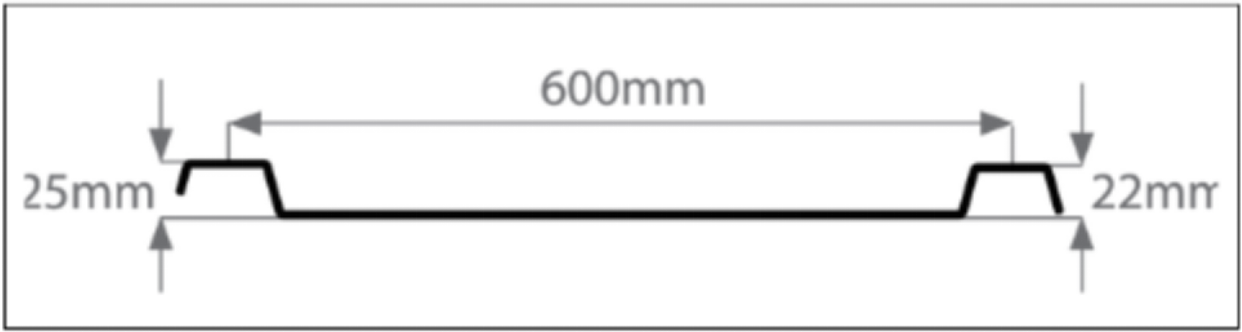

PolyGlaze® is lightweight and designed to install directly onto 50 mm rafters at 600 mm centres—no need for additional purlins. It’s perfect for DIYers and home renovators looking for a clean, professional finish.

Built to Withstand Aussie Weather

With high resistance to wind and hail, and UV-blocking technology that filters 99.9% of harmful rays, PolyGlaze® keeps your outdoor area safe and enjoyable all year round.

Available in Clear and Grey Tints

Choose the tint that best suits your space—whether you’re chasing natural light or a bit more shade.

Made for Australian Backyards

Ideal for patios, pergolas, carports, gazebos, and pool areas, PolyGlaze® sheets are engineered to handle harsh Aussie conditions and are covered by a 10 Year Warranty for total peace of mind.

Available Tints: Clear (84% Light Transmission), Grey (53% Light Transmission)

Panel Thickness: 3.0 mm

Cover Width: 600 mm

Sheet Lengths: 2000 mm, 4000 mm, 6000 mm

Weight: 3.97 kg/m²

U-Value: 5.45 W/m²·K

UV Protection: Blocks 99.9% UV (single-sided)

Applications: Pergolas, carports, porches, walkways, awnings, gazebos, pool covers, entrances

Fire Ratings: PolyGlaze® complies with the most demanding international fire resistance standard in the field of plastics – EN 13501-1 + A1 and UL 94.

Roof Angle: Minimum 5º pitch

Installation: Fix directly to rafters at 600 mm centres (no purlins needed). Max batten spacing: 1200 mm.

Tools Required: Standard hand tools; fine tooth blade for cutting recommended

Ampelite recommend the use of self adhesive tape on battens to reduce noise created by expansion and contraction of the sheeting.

Warranty

PolyGlaze® panels are manufactured under an ISO 9001:2015 certified quality system, ensuring consistency, safety, and long-lasting performance.

Every panel is backed by a 10-year limited warranty, offering peace of mind and assurance of quality.

For full warranty terms and claim procedures, please contact your local Ampelite office.

We’re here to help!

For all enquiries please email us using the form below and one of our friendly team members will touch base with you.

Opening hours:

6.00am – 4.30pm Monday-Friday.