With state-of-the-art metal stamping, rollforming and folding machines and combined with supply partnerships with leading industry-respected manufacturers, All Metal is able to offer a complete range of roofing and walling, rainwater goods, architectural panels, custom and standard flashings and metal roofing accessories.

At All Metal, we understand that providing great products is not enough when it comes to delivering a superior service to our customers. That’s why we’ve built a business focused on the complete needs of our customers and invested in the facilities and capabilities that support our vision to be the professional metal contractors first choice.

With manufacturing centres in Wetherill Park, Brookvale & Padstow and a Sub Branch in Mt Kuring gai in Sydney, Tuggerah on the Central Coast and Thornton in Newcastle, enables us to supply our products from Nowra, Sydney and North to Nelson’s Bay on a daily basis.

Our leadership team has over a hundred years combined metal building products experience and understand that relationships between customer and supplier are a part of any successful business.

Supported by our core values of safety, integrity, and excellence, All Metal strives to build strong, mutually beneficial relationships by delivering a superior customer experience to every customer, every time.

We believe we are the leading manufacturer in NSW in our Market segment.

The All Metal Partners have well over 100 years combined experience in:

All Metal has the scale and adaptability to deal with any size project ranging from a small residential renovation or new home to a large Commercial/Industrial Development. We offer:

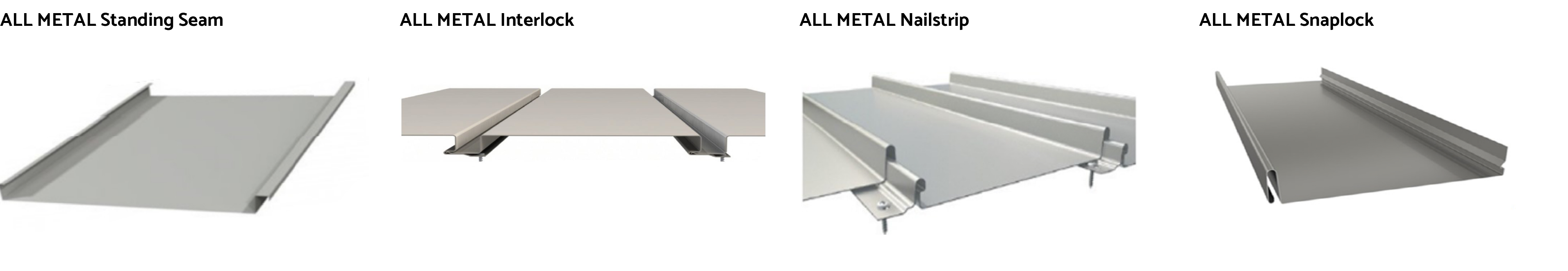

All Metal manufactures its own range of the latest architectural cladding products. With Standing Seam and Interlock panel options available, All Metal’s architectural cladding range can be used to create a distinctive and modern architectural statement.

If one of the All Metal architectural cladding profiles doesn’t exactly suit your requirements, then we are also able to supply options from other well-known metal cladding manufacturers.

As with all the products we supply, All Metal’s technical experts are always available to assist with design and installation advice and guidance.

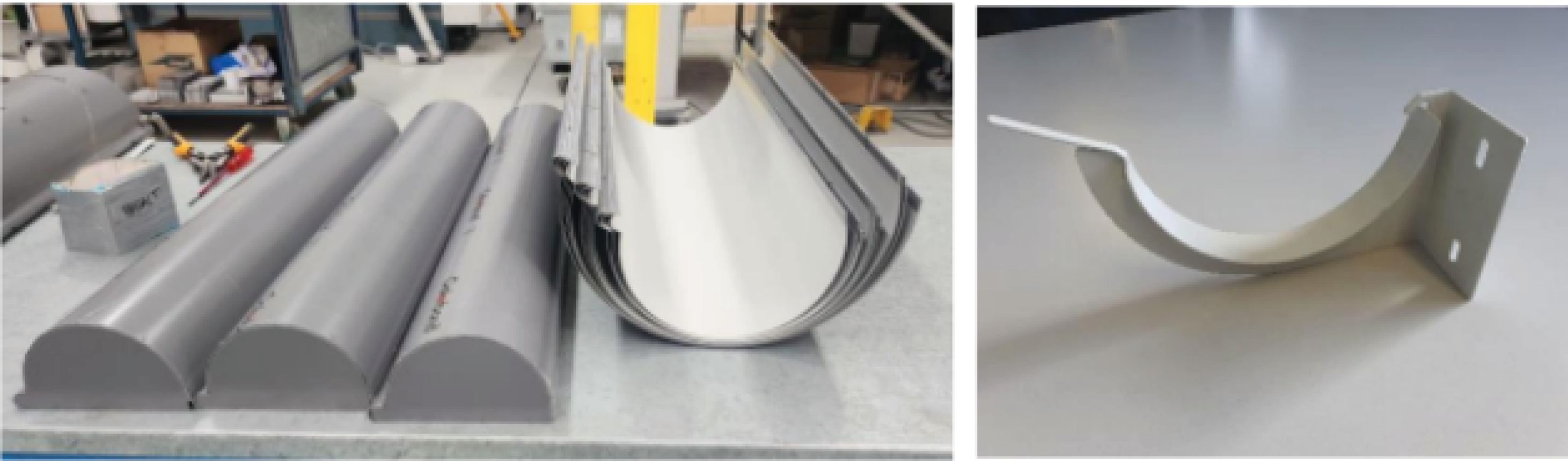

All Metal manufactures its own Commercial Half Round Gutters and Heavy Duty A4 Brackets from 150mm up to 400mm including a complete range of accessories to go with them.

Commercial Square/Rectangle Gutters and Heavy Duty A4 Square Brackets

All Metal has the unique capability to manufacture downpipes up to 8m long;

We are able to supply these products in a range of materials including;

Major manufacturing facilities supply product across the state through our five company outlets located in Sydney, Central Coast and Newcastle. All Metal also has in-house powder coating capability.

To provide the best quality products, over $20 million has been invested in state-of-the-art stamping, forming and folding machines. The latest All Metal Australia investment of over half million dollars is a SWI Duplex 8200 Gen III Folder. This Australian built folder offers all the latest technology including fully automated folding. It has 280 degrees of Free Space with up to 150 degrees of Folding Angle, allowing for even the most difficult design to be produced up to 8.1m in length.

From our custom-designed raw materials storage racks, through to our production handling equipment to our finished product storage and delivery packaging, we ensure that every All Metal product is accurately identified and carefully handled to eliminate the risk of damage.

Our in-house developed integrated order, stock and production management systems connect every part of our business and ensure orders seamlessly and accurately progress from receipt to production to pick up and delivery.

40 Company Vehicles : 16 Trucks and 18 Racked Utes